AI-Enabled Operations

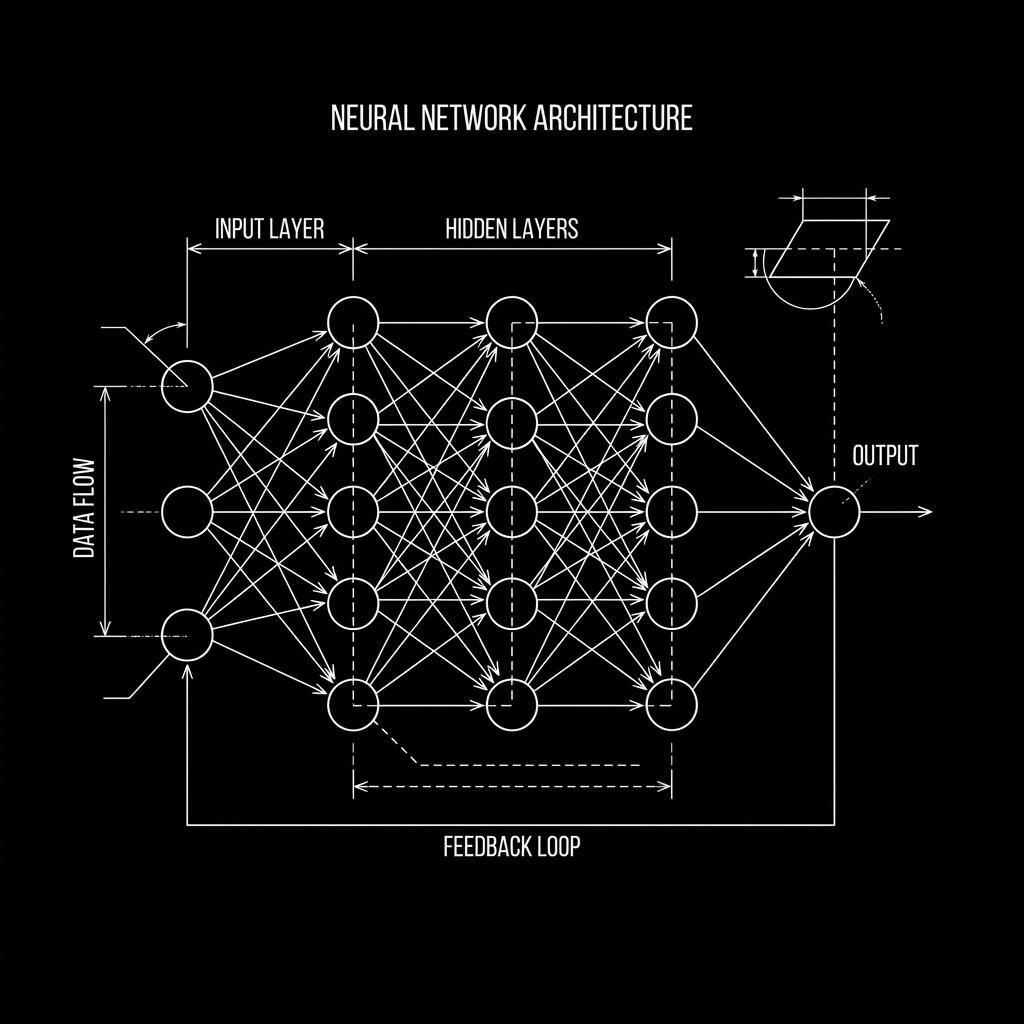

Moving beyond 'pilot purgatory'. We deploy practical, scalable machine learning models that drive real-time operational decisions.

The industrial world is awash in data but starved for wisdom. At LOCHS RIGEL, we build the "last mile" of industrial AI—connecting raw telemetry from the shop floor to high-fidelity algorithms that predict failures, optimize setpoints, and automate quality control in real time.

AI Deployment Domains

Predictive Maintenance

Transitioning from calendar-based maintenance to condition-based interventions using vibration, heat, and power signature analysis.

Vision-Guided Quality

Deployment of deep learning models that detect micron-level defects at line speed, far surpassing manual human inspection throughput.

Autonomous Setpoint Tuning

Reinforcement learning agents that continuously tune PID loops and process parameters to maximize yield while minimizing waste.

Demand-Sensing Forecasting

AI models that integrate external market signals with shop-floor capacity to optimize inventory buffers and production scheduling.

Our Industrial Data Stack

We remain vendor-neutral but maintain deep engineering expertise in the modern industrial cloud and edge ecosystem.

Validate Your Strategy

Stop burning capital on vague data science pilots. We help you build a roadmap for production-grade AI.

Production Focus // No Pilot Purgatory