Industrial OEMs

Transitioning from heavy equipment sales to intelligent, outcome-based service models. We help OEMs build the digital DNA of the future.

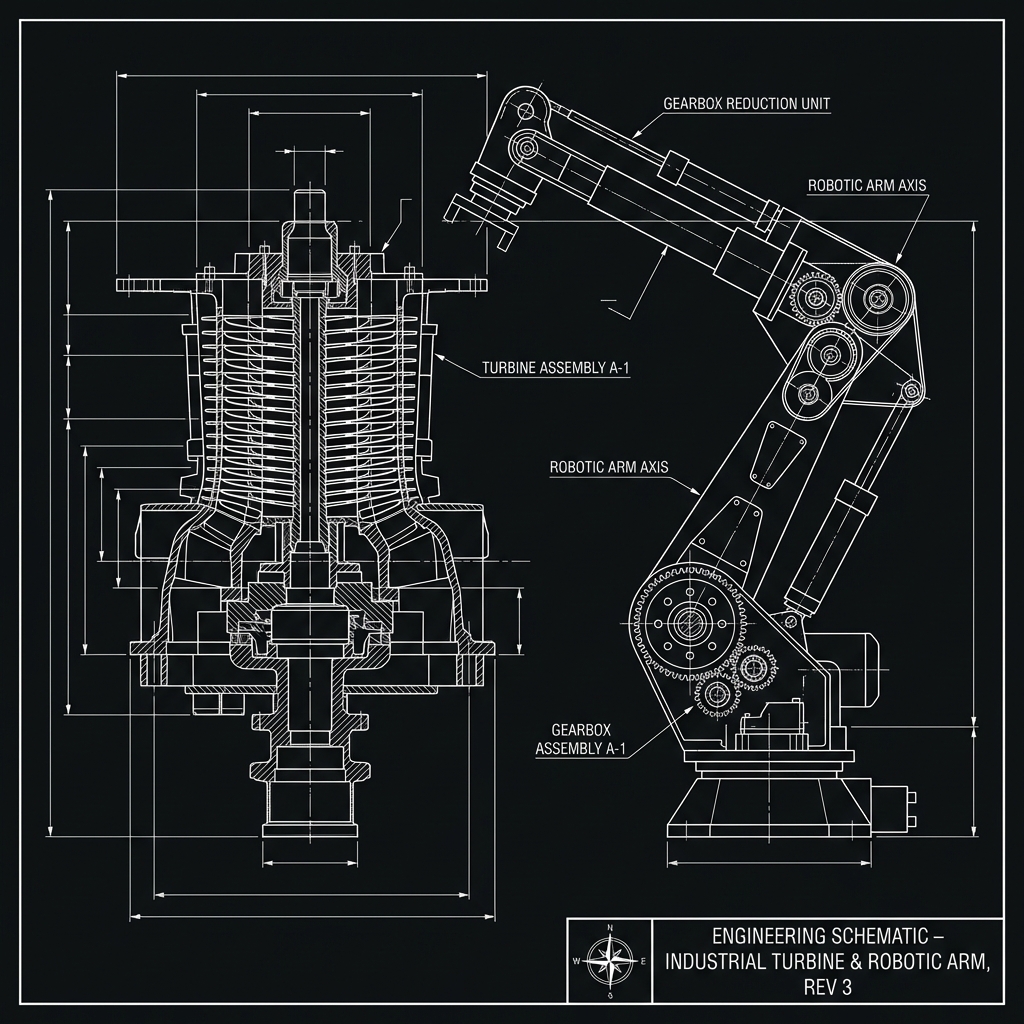

For equipment manufacturers, hardware is no longer the sole differentiator. The future lies in intelligent machines that self-optimize, predict their own failures, and integrate into customer ecosystems. AT LOCHS RIGEL, we help OEMs transform into high-margin software and service providers.

Digital Value Levers

Connected Asset Ecosystems

Embedding advanced telemetry and edge compute to enable remote performance monitoring, over-the-air (OTA) updates, and fleet-wide optimization.

Servitization (MaaS)

Designing the business models and billing infrastructure for 'Machine-as-a-Service'. We align your revenue with your customers' actual uptime and output.

Digital Customer Experience

Building high-performance portals and dashboards that give your customers deep visibility into their asset performance and lifecycle health.

Agile Control Engineering

Helping mechanical engineering cultures embrace software best practices. We establish CI/CD pipelines for industrial control code and PLC logic.

The Outcome Advantage

We believe that in the next decade, the most successful OEMs will be those who sell reliability, not just iron. We provide the technical architecture to make this pivot profitable while minimizing technical debt and operational risk.

Evolve Your Model

Transform your business model from one-time sales to recurring, high-margin digital service revenue.

Recurring Revenue // Digital DNA