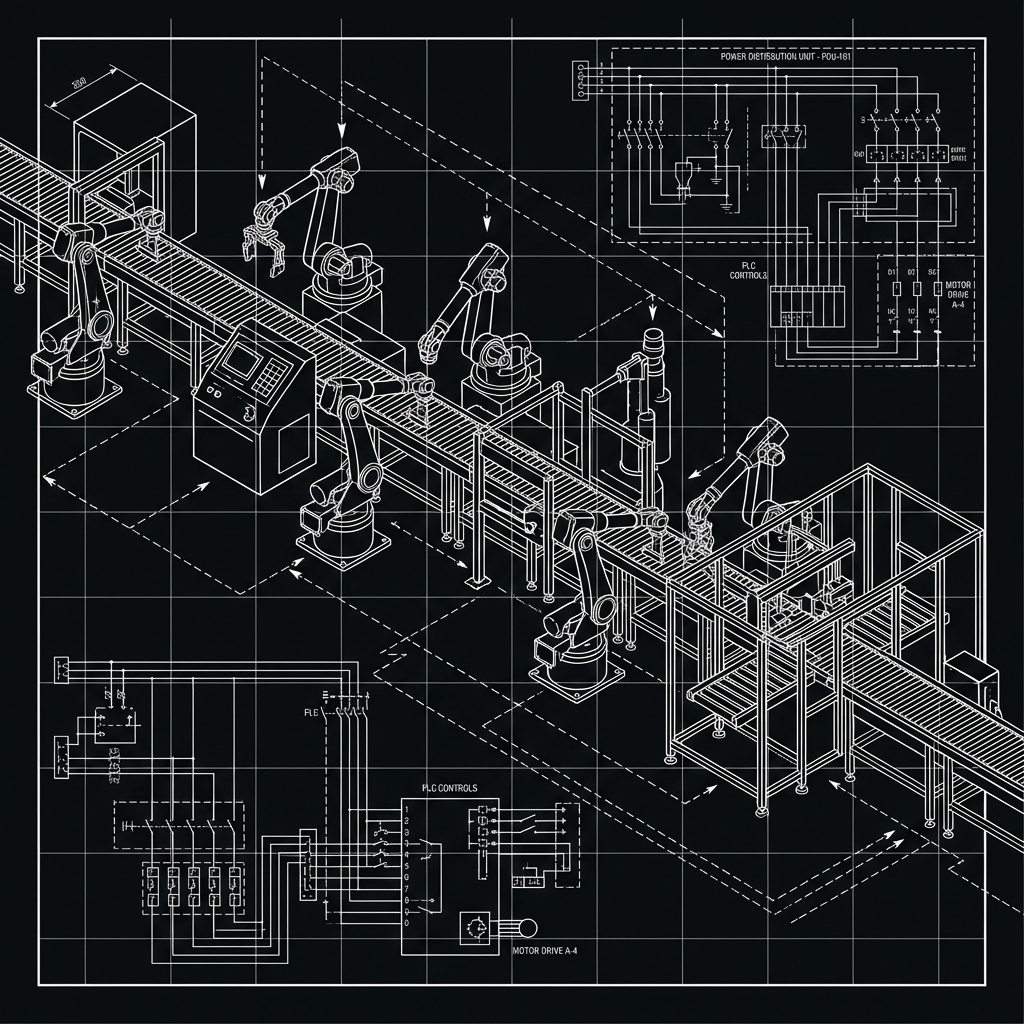

Advanced Manufacturing & Automation

From legacy PLC modernization to fully autonomous production lines. We design the physical and digital infrastructure of the future factory.

Automation is not just about replacing labor; it is about precision, repeatability, and data velocity. At LOCHS RIGEL, we help manufacturers navigate the complex landscape of Industry 4.0, from selecting the right robotics to architecting the edge-to-cloud data fabric that powers them.

Technical Pillars

Robotics & Kinematics

Design and integration of collaborative robots (cobots), AMRs, and high-speed pick-and-place systems tailored for complex assembly.

Legacy Modernization

Strategic extraction of value from brownfield PLC/SCADA systems without the risk and cost of full rip-and-replace cycles.

Industrial IoT (IIoT)

Architecting secure, scalable sensor networks that provide real-time visibility into machine health, vibration, and energy usage.

Physics-Based Twins

Advanced digital twin simulation to validate production changes, cycle times, and robotic paths before a single bolt is turned.

Digital Twin: Automotive Assembly

The Challenge

Global manufacturer faced high scrap rates and downtime due to manual assembly variations in high-precision automotive components.

The Solution

Deployed synchronized digital twin physics-based simulation with integrated high-resolution computer vision and real-time robotic feedback.

The Outcome

96%

Drop in Scrap

$4M Annual Yield Impact

0.5% FINAL RATE

Engineer to Engineer

Discuss your specific automation blockers with our technical leads—not sales reps.

Validated OT Expertise // Direct Access