The PLC Modernization Trap: Why Replacing Legacy Hardware Isn't a Strategy

The PLC Modernization Trap: Why Replacing Legacy Hardware Isn't a Strategy

Analyzing the hidden technical debt in 1-for-1 controller replacements and the case for a unified data layer in modern automation.

Many manufacturers today are facing a "silent crisis" on their factory floors. In corners of plants across the globe, industrial automation systems that were installed in the late 1990s and early 2000s are reaching the end of their supported lives. These systems—centered around Programmable Logic Controllers (PLCs)—are the nervous systems of global production. When they fail, lines stop; when they age, they become vulnerable to cyber-threats and "unobtainium" spare parts.

Chipping away at this risk, manufacturing executives treat the replacement of these aging controllers as a routine maintenance task—a "necessary evil" to avoid unplanned downtime. They find a modern version of the same brand, hire a system integrator to "lift and shift" the logic, and declare victory once the machine starts moving again.

// DATA_SOURCE: LEGACY AUTOMATION AUDIT DATA // 2025

At LOCHS RIGEL, we call this the PLC Modernization Trap. It is a strategy that keeps your plant running today while ensuring it remains competitively stagnant tomorrow. This "like-for-like" hardware replacement is the most expensive way to stay exactly where you are.

Data > Hardware

"True modernization is a transition from 'Hardware-Centric Control' to 'Data-Centric Intelligence'. If your new PLC isn't an open telemetry node, you haven't modernized."

The Anatomy of the Trap: Why "Lift and Shift" Fails

When you perform a 1-for-1 replacement of a legacy controller, what you are actually doing is Modernizing your Technical Debt. You are taking operational logic that was written under the hardware constraints and networking limitations of thirty years ago and moving it to a faster processor—without fixing the underlying architectural flaws.

1. The Siloed Intelligence Problem

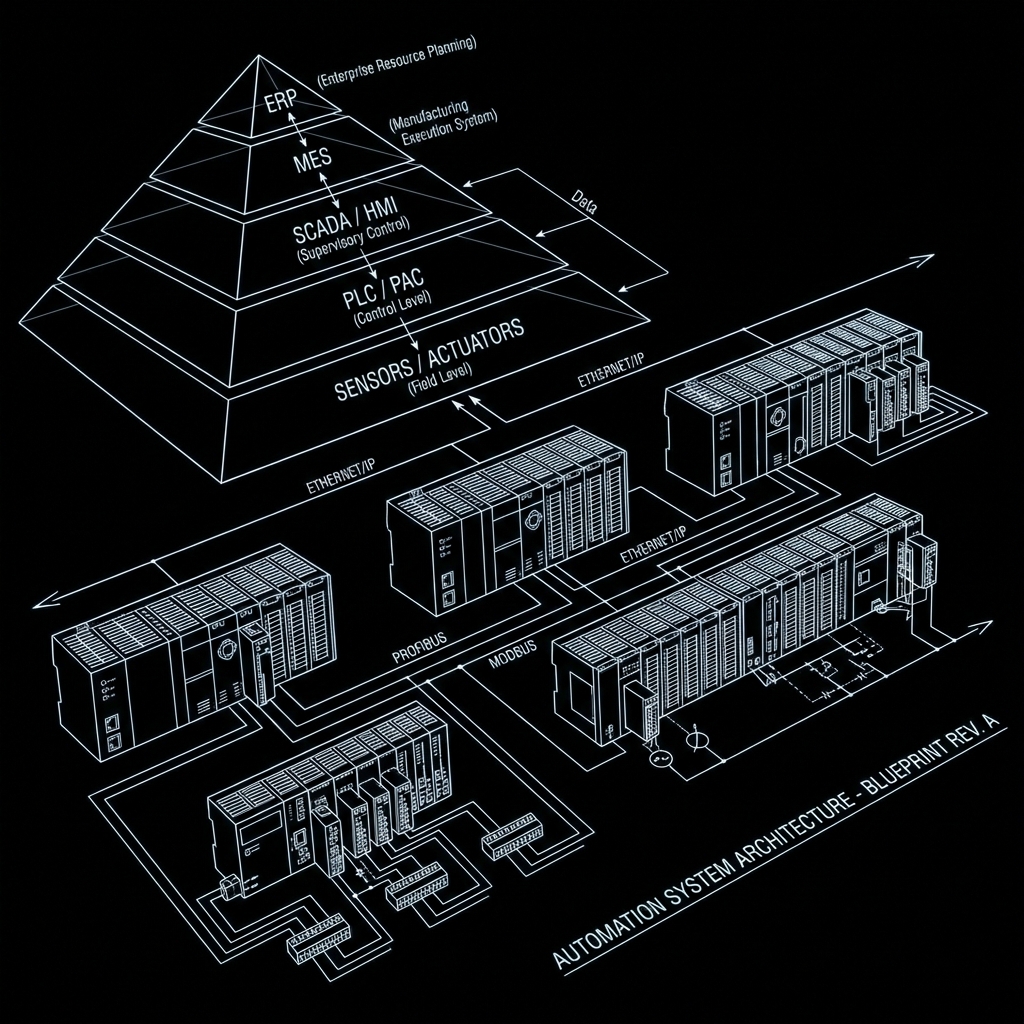

Legacy PLCs were designed to operate in a "command and control" vacuum. They follow a rigid hierarchy (the ISA-95 model, or the "Automation Pyramid") where data must pass through layers of middleware, SCADA, and MES before reaching a person who can make a business decision.

A modern hardware swap doesn't fix this. The new PLC is faster and has more memory, but it remains a "black box." The critical data about your motor's thermal signature or your valve's latency is still trapped inside proprietary registers, inaccessible to the AI and data analytics tools that your boardroom is investing in.

2. The Brittle Integration Cycle

"Lift and shift" modernization perpetuates point-to-point integration. You end up with bespoke, non-standard connections where the PLC speaks only to one specific HMI or one specific SCADA system via a proprietary driver.

This creates an "Integration Tax." Every time you want to add a new sensor or a new dashboard, you have to pay a programmer to open up the PLC code, map new tags, and modify the HMI. This lack of flexibility is what kills the ROI of "Digital Transformation" initiatives.

The Proprietary Tax

"Vendor lock-in is a silent EBITDA drain. Every proprietary driver you install today is a future integration cost you'll have to pay tomorrow."

3. The Proprietary Tax & Vendor Lock-In

By simply upgrading to the next version of a legacy vendor's PLC, you are re-signing a contract for another decade of vendor lock-in. You remain beholden to their expensive, proprietary communication modules and their license-heavy development software—tools that don't speak the modern language of the cloud (JSON, MQTT, REST).

A Better Way: Transitioning to the Software-Defined Factory

To break free from the trap, modernization must be viewed as a transition from Hardware-Centric Control to Data-Centric Intelligence. Here is the LOCHS RIGEL blueprint for a future-proof automation stack.

Pillar 1: Decoupling Logic from the Iron

The most radical and necessary step in modern automation is the shift toward Software-Defined Control.

In a traditional plant, the "Logic" (the code) and the "Iron" (the CPU) are the same thing. If the controller dies, the code is gone. If you want to run the code elsewhere, you can't.

We are moving our clients toward Virtual PLCs (vPLCs) and containerized control logic. By using high-performance industrial edge PCs rather than proprietary "bricks," we can run control logic in an environment that is treated like a modern data center.

- One-Click Updates: We can push updates to a hundred machines simultaneously.

- Automated Redundancy: If one edge PC fails, the logic can automatically failover to another node in the plant.

- Hardware-Agnostic: You are no longer tied to one vendor's supply chain issues.

Pillar 2: The Unified Namespace (UNS)

This is the single most important architectural component of a modern plant. Instead of a "Pyramid" where data is throttled at every layer, we implement a Hub-and-Spoke Data Bus.

Every asset, from a simple temperature sensor to a million-dollar robot, publishes its data to a central broker in a standardized format (Site/Area/Line/Machine/Sensor).

- Zero-Custom Mapping: When a new machine is modernised, it publishes its "Digital Twin" to the UNS.

- Democratized Data: Now, any other system—be it a local dashboard, a global ERP, or a predictive maintenance AI—can "subscribe" to that data instantly. You have removed the "Integration Tax" permanently.

Pillar 3: Report-by-Exception (MQTT/Sparkplug B)

Legacy systems use "polling," where a server constantly asks a PLC "is it on? is it on? is it on?" This wastes up to 90% of your network bandwidth on useless information.

We utilize MQTT with Sparkplug B. This is a "Report-by-Exception" protocol. The machine stays silent until something changes. This allows for massively scalable networks, lower latency, and immediate notification of system health.

The Execution Roadmap: How to Modernize Correctly

If you are facing a large-scale legacy hardware obsolescence event, stop the purchase orders and follow this frame-of-reference:

Phase 1: The Data Audit (Stop the Logic-Only Thinking)

Don't ask "which PLC is broken?" Ask "what information is currently trapped in our lines that would help us increase OEE by 5% if we could see it in real-time?" The goal of modernization is to turn every asset into a telemetry source.

Phase 2: Build the Data Fabric Before the Hardware

Implement your Unified Namespace broker (e.g., HiveMQ or EMQX) and your bridge layer. This is your "Ground Truth" foundation. Every single modernization project from that point forward must be required to "plug in" to this namespace.

Phase 3: Hardware-Agnostic Pilots

Start a pilot on a non-critical line using an Edge-based controller or a PLC with built-in MQTT/Sparkplug B support. Prove that you can see the machine's state in a cloud dashboard within 15 minutes of installation without writing a single line of custom middleware code.

The Walkaway: Three Challenges for Operations Leaders

- "Can we see it in the cloud today?" If I asked you for the live motor temperature of Machine 4 in Plant B right now, can you give it to me? If the answer is "I'd have to call the plant manager," you have a Silo problem, not a Hardware problem.

- "What is our Integration Tax?" Look at your last three automation projects. What percentage of the budget went to "Software Licenses" and "Manual Tag Mapping"? That is capital that should have been spent on optimizing the process.

- "Are we buying more Technical Debt?" Every time you buy a proprietary controller that doesn't support open Data protocols, you are mortgaging your plant's future flexibility for a short-term maintenance fix.

Modernization is not a maintenance event; it is a once-in-a-generation opportunity to redefine your operational DNA.

The goal is no longer just to "keep the machine running." The goal is to turn your factory into a self-describing, self-optimizing intelligence organism.

At LOCHS RIGEL, we provide the architectural blueprints to ensure your modernization project doesn't just replace the "Iron," but truly upgrades the "Intelligence." Stop the swap. Start the transformation.