The EV Battery Yield Crisis: Why Scrap Rates are the Biggest Threat to Global Electrification

The EV Battery Yield Crisis: Why Scrap Rates are the Biggest Threat to Global Electrification

A deep dive into the chemistry and process control challenges currently bottlenecking the automotive transition. Why 30% scrap rates are unacceptable.

The global conversation around the electric vehicle (EV) transition is curiously single-threaded. Open any financial publication or climate report, and you will see a relentless focus on two variables: the global supply of critical minerals (lithium, cobalt, nickel) and the consumer adoption rate (charging infrastructure, price parity).

However, there is a third, more urgent bottleneck that is rarely discussed in the boardroom: The Battery Yield Crisis.

As the world's leading automotive OEMs rush to stand up "Gigafactories" to secure their future, they are colliding with a devastating operational reality. At LOCHS RIGEL, we have observed multiple new production lines where 30% or more of the initial output is discarded as scrap. In a high-volume industry where margins are razor-thin, a 30% scrap rate isn't just an inefficiency; it is a structural threat to the economic and environmental viability of electrification.

// DATA_SOURCE: BATTERY GIGAFACTORY OPERATIONAL BENCHMARKS

Yield is the Only Metric

"Gigafactory success is measured at the output dock, not the ribbon cutting. A 30% scrap rate is a multibillion-dollar write-down waiting to happen."

The Precision Paradox: Baking a souffle at 80 Meters per Minute

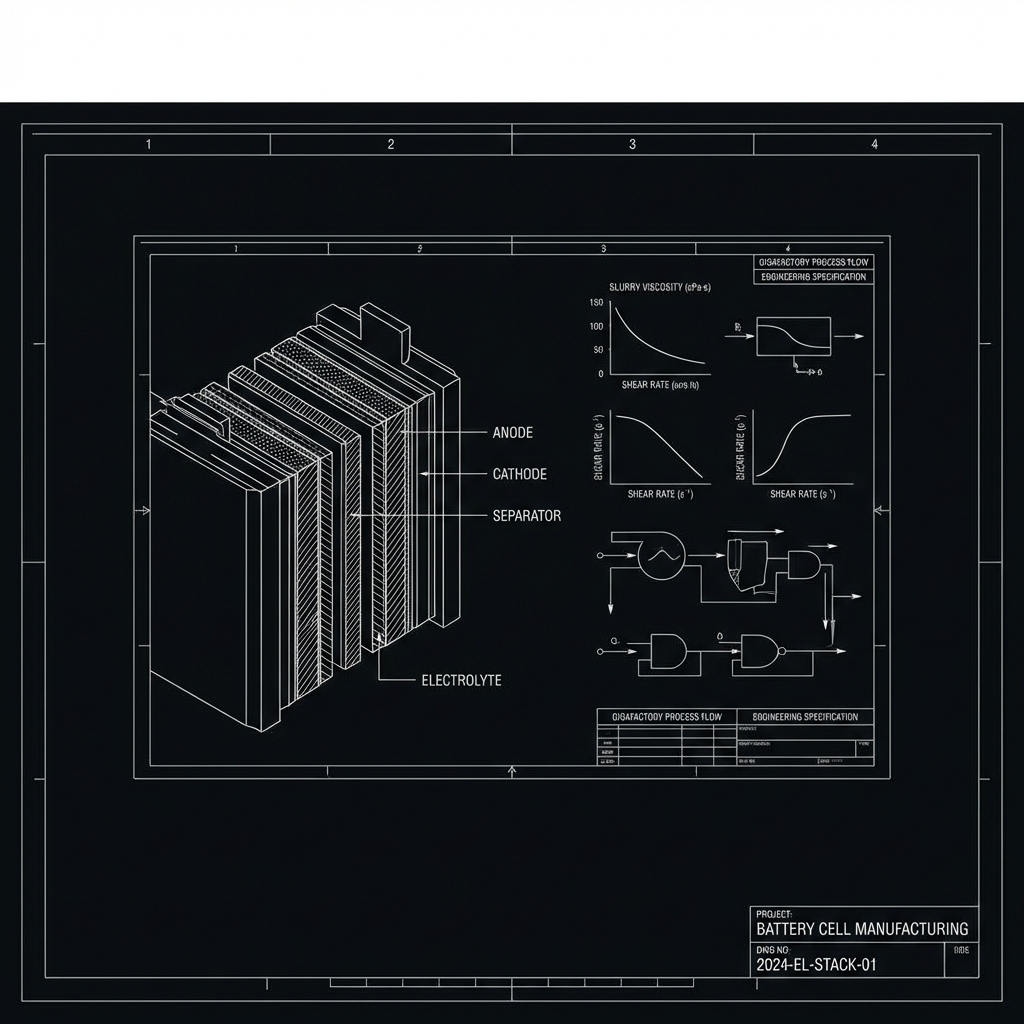

Manufacturing a battery cell is not like assembling an engine. It is not a purely mechanical process. Instead, it is more akin to baking a highly sensitive, miles-long, multi-layered souffle. It is a high-speed chemical process that must be maintained within microscopic tolerances across massive "Web-Handling" machines.

Why the Yield is Failing on the Floor:

-

The "Black Box" of Slurry Chemistry The heart of the cell is the "Slurry"—a complex mixture of active materials, binders, and solvents. This slurry must be perfectly homogeneous. Yet, in most plants today, the mixing process is disconnected from the downstream results. If the slurry's viscosity drifts by even 3% due to a change in ambient humidity or a slight variation in the purity of a raw material batch, the subsequent coating and drying stages are doomed. By the time that "Bad Slurry" has been detected as a failed cell, the line has produced fifty thousand meters of defective electrode.

-

The Thermal Inertia of the Drying Oven The drying ovens used to "set" the electrode materials are gargantuan assets, often dozens of meters long. They are energy-intensive and possess massive thermal inertia. If a high-precision sensor detects a coating defect downstream, the system cannot simply "turn down the heat." It takes far too long for the oven's temperature profile to adjust. Without predictive control, the line simply continues to produce scrap for the next twenty minutes while the heat stabilizes.

-

Microscopic Burrs and the "Short-Circuit" Risk At the assembly stage, the battery layers are stacked and folded at incredible speeds. A slight misalignment—measurable only in microns—can create a tiny "burr" or a misaligned separator. On the day of manufacture, the cell might look fine. But during its first charge-discharge cycle, or six months into its life in a vehicle, that burr can trigger a short circuit.

The LOCHS RIGEL Strategy: Moving to "Deterministic Process Control"

The battery industry has traditionally relied on "End-of-Line" testing to ensure quality. At LOCHS RIGEL, we believe this is a recipe for bankruptcy. You cannot "test" quality into a battery; you must engineer it into the process.

1. High-Frequency Telemetry & Synchronicity

The first step in solving the yield crisis is overcoming the "Data Lag." We architect data stacks that capture sensor data at the millisecond level across the entire line.

Synchronous Truth

"Data is useless without synchronicity. Solving yield drift requires millisecond-level correlation between the mixing slurry and the final cell performance."

Crucially, we use a Unified Namespace (UNS) to ensure all that data is perfectly synchronized. This allows us to perform "Causal Linking"—tracing a final cell failure back to the specific viscosity readings of the slurry mix from five hours prior. Without this millisecond-level synchronicity, your data is just noise.

2. The Deterministic Digital Twin

We build physics-based models of the drying and electrolyte-filling stages. Instead of waiting for a defect to appear, the Digital Twin uses real-time ambient inputs (humidity, pressure, raw material batch data) to simulate the "Next 10 Minutes" of production.

The system then suggests anticipatory adjustments to the line speed and oven setpoints. If the humidity rises, the line speed drops by 0.5% automatically to maintain the drying profile. This is shifting from "Reactive Scrap Management" to "Predictive Yield Preservation."

3. Granular Traceability (The Battery Passport)

We implement "Cell-Level Traceability"—the foundation of the Battery Passport. Every single cell is assigned a unique digital ID. We track every variable that specific cell was exposed to.

- Which batch of slurry did this cell come from?

- What was the exact humidity in the oven when it passed through?

- What was the tension on the separator roll at the moment of stacking?

When a batch of cells shows a performance dip, we don't have to scrap the entire shift's production. We surgically identify and remove only the cells that were exposed to that specific process drift.

The Economic Stake: Why Yield is the Only Metric That Matters

For an automotive OEM, the difference between an 80% yield and a 95% yield in their gigafactory is not just a "cost saving"—it is the difference between a profitable EV program and a multibillion-dollar write-down.

- Capital Efficiency: Every asset on your floor costs hundreds of millions of dollars. If 20% of the time it is producing scrap, you are effectively burning 20% of your capital investment.

- Environmental Integrity: You cannot build a "Green" car with a "Grey" process. Scrapping 30% of your energy-intensive batteries at the factory dock destroys the CO2 advantage of the vehicle before it touches the road.

- Market Speed: The winner of the EV transition will be the firm that can scale production the fastest. You cannot scale a broken process; it only creates more scrap at a higher velocity.

The Walkaway: Three Hard Truths for Auto Executives

- Stop Measuring "Nameplate Capacity": Total theoretical GWh means nothing. The only metric that matters is Saleable Yield per Square Meter of Factory Floor.

- The "Yield Gap" is an Engineering Debt: If your plant relies on manual adjustments and "Post-Mortem" testing, you have a massive technical debt that will prevent you from ever reaching profitability.

- Data is the New Active Material: Your ability to capture, correlate, and act on high-frequency operational data is as critical to your survival as your access to lithium and cobalt.

The battery leaders of the next decade won't be those with the largest buildings, but those with the most precise control over the physics of the line. At LOCHS RIGEL, we provide the control architecture and the technical "Nervous System" that turns Gigafactories from scrap-machines into yield-engines.

The yield crisis is solvable, but only for those willing to admit that the problem is in the physics, not the supply chain.